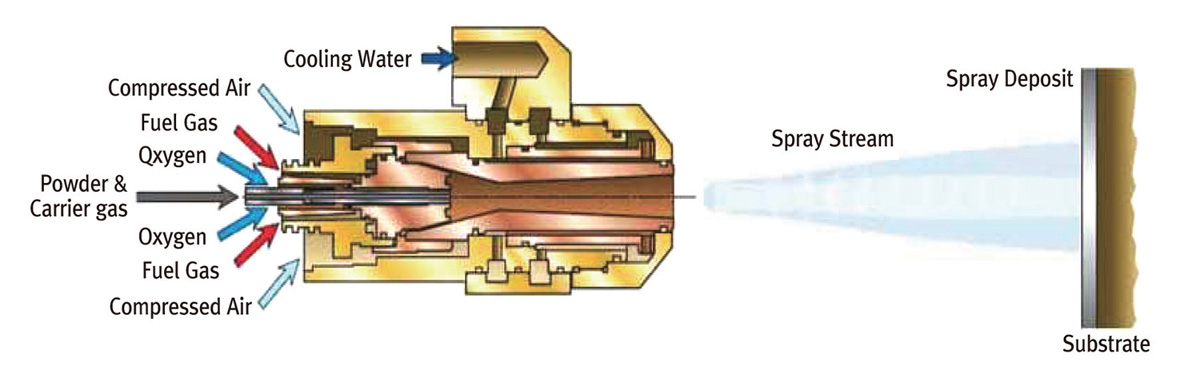

H.V.O.F Coating

H.V.O.F system

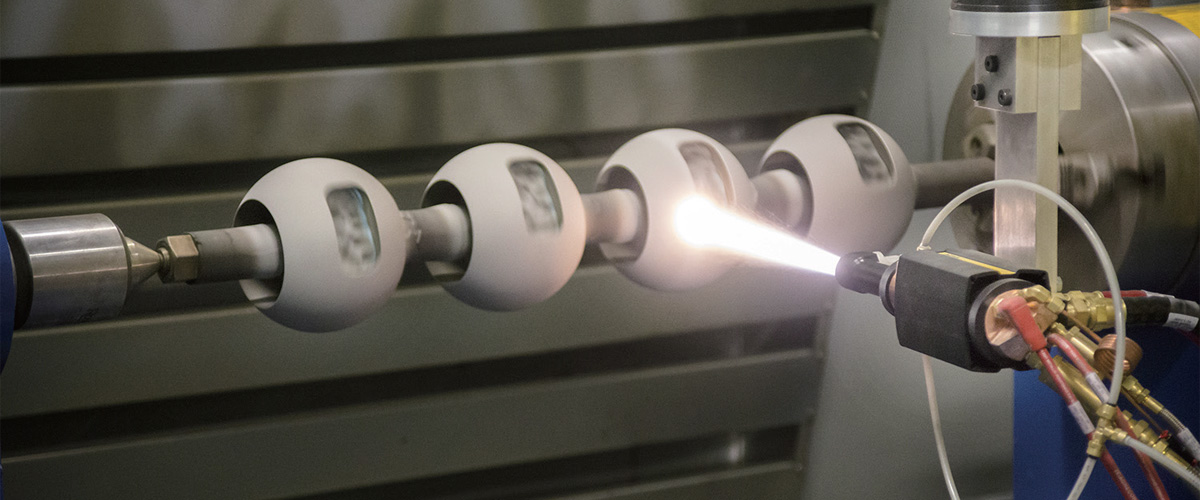

Industrial Robot

| Application field |

It improves the chemical resistance of facilities in the chemical sector. It impoves the corrosion resistance of facilities exposed to sea water environment. It improves the abrasion resistance of stirring facilities such as screws. |

|---|---|

| Coating Materials |

Tungsten Carbide : Recommended for application field on the materials prone to abrasion and have strong adhesion to high density materials. Tungsten Carbide - Nickel - Chrome Compared to Tungsten Carbide coatings, it has excellent corrosion resisance, making it ideal for application field of sea water such as hydraulic rods. Chromium Carbide : It has high fine hardness and increases abrasion and friction resistance without brittleness. |

| Process Condition |

Types of heat sources : Oxygen + Fuel Temperature of heat source : high temperatureConditions(2,700~3,100℃ level) Injection Speed: Ultra high speed (above 2,000 m/sec). AAdhesion: above 10,000psi Base material temperature: below 200℃ |

| Process Characteristics |

Molten particles are sprayed at ultra-high speed to form a fine and even coating. (low material loss, high adhesion, low process rate, high density) Higher coating thickness is formed compared to other spraying processes. Less thermal deformation of the base materials The corrosion resistance and wear resistance are greatly improved. |