Plasma Coating

Industrial Robot

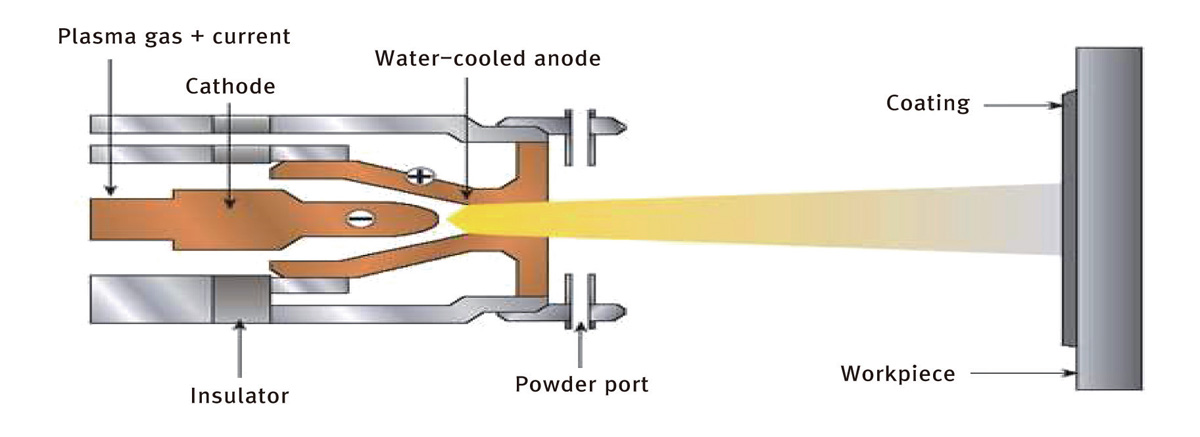

Ceramic spray system

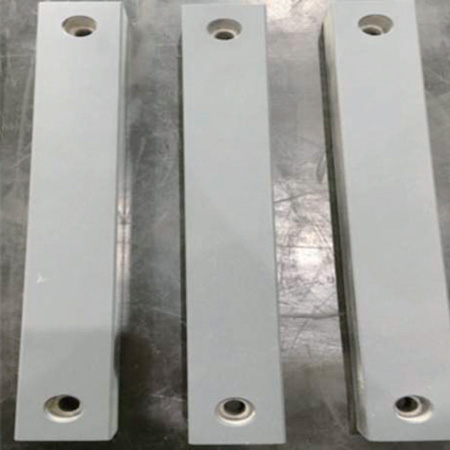

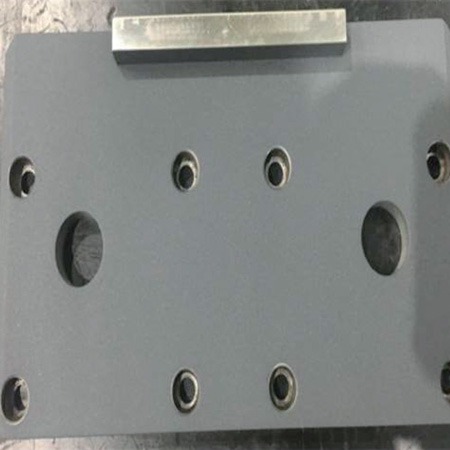

| Application field |

Improved insulation performance of semiconductor equipment. Improved heat resistance and heat shielding coatings for industrial gas and air craft turbines, etc. Good for the use of equipment requiring high hardness (rockets, nozzles, etc) |

|---|---|

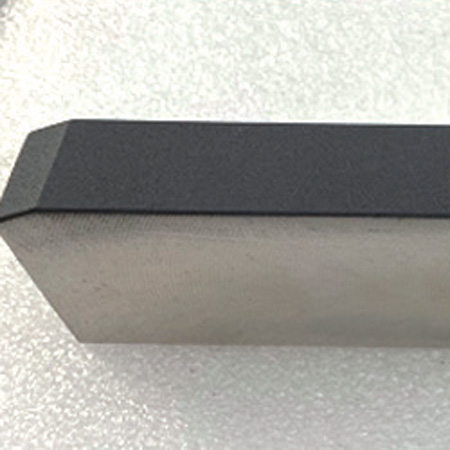

| Coating Materials |

Tungsten Carbide : Recommended for wearable application fields, having high adhesion to high density materials. Alumna - Titania : It provides high corrosion resistance and is ideal for the nature of the marine industry. Zirconia : It has low thermal conductivity and the highest hardness at room temperature. |

| Process Condition |

Types of heat sources : Inert Gas Temperature of heat sources : Ultra-high temperature(10,000 ~16,500℃) Injection speed : High speed (400 m/sec) Adhesive strength : Above 10,000 psi Raw material temperature : Below 200℃ |

| Process Characteristics |

The temperature of the heat source is high so it is applicable to materials with various properties. Coating material is completely melted so the coating density is high and smooth. The thermal deformation of the base material is small. It provides corrosion protection and high thermal and oxidation resistance and wear resistance. |