Fusing Coating

Flame spray

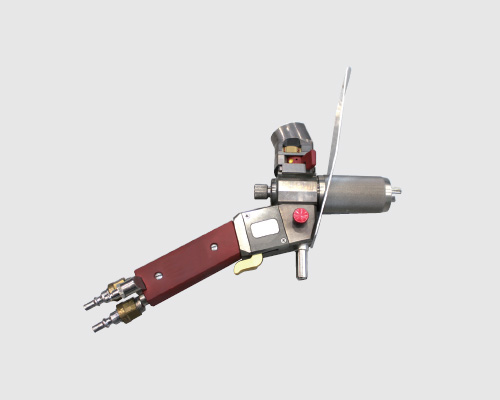

Portable spray

| Application field |

Improved chemical resistance of equipment in the chemical field Improved corrosion resistance of equipment exposed to seawater environment Improved wear resistance of agitation equipment such as screws |

|---|---|

| Coating materials |

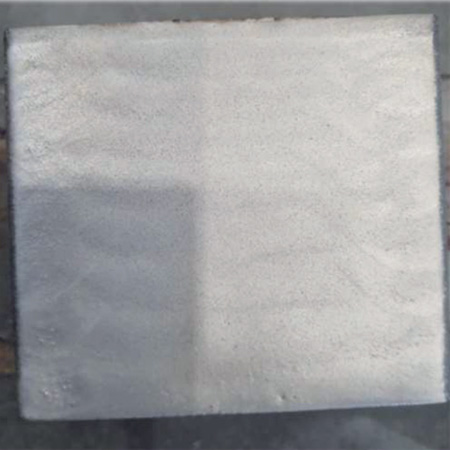

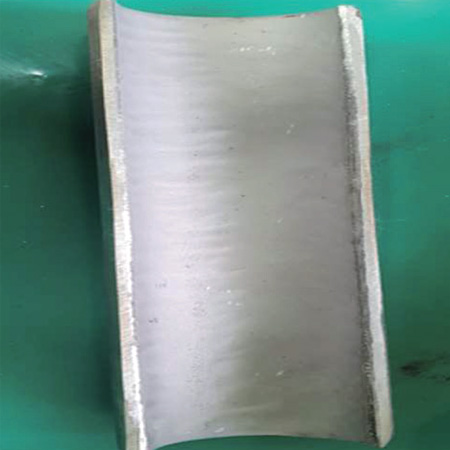

Tungsten Carbide - Nickel - Chrome : Excellent corrosion resistance compared to Tungsten Carbide coating, making it ideal for seawater applications such as hydraulic rods Chromium Carbide : Increased wear and friction resistance with high microhardness and no brittleness |

| Process condition |

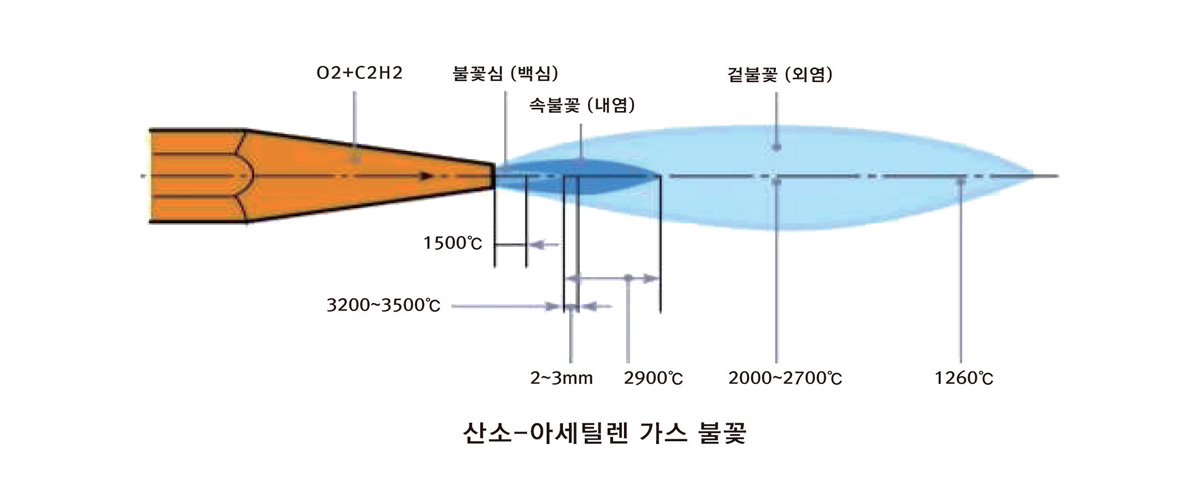

Types of heat sources: oxygen + fuel Temperature of heat source: high temperature (3200 ~ 3500℃) Injection speed: low speed Base material temperature: over 500℃ |

| Process characteristics |

Precision coating for thin base materials and complex shape parts Formation of high coating thickness compared to other thermal spray processes Coating thickness is easily adjusted, so it is easy to repair products with severe wear Simplified equipment makes it easy to move around and relatively inexpensive |