Hardfacing Welding

| Application field |

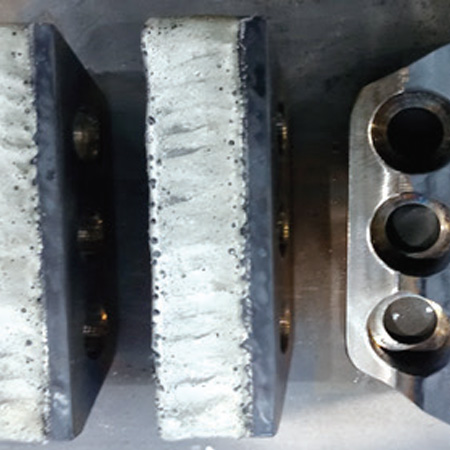

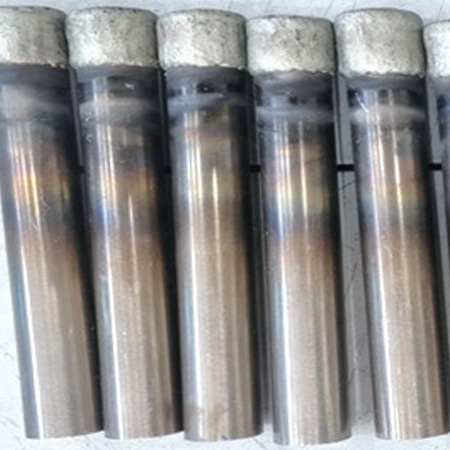

Useful for industrial applications such as cutting tools and wear components Improved chemical resistance of equipment in the chemical field Improved wear resistance of agitation equipment such as screws |

|---|---|

| Coating materials |

Tungsten Carbide : Excellent wear/heat/resistant welding rod can be applied to all materials Stellite : It has very good characteristics that do not reduce hardness even at high temperatures, so it has very high compression, corrosion resistance, wear resistance, and thermal resistance. |

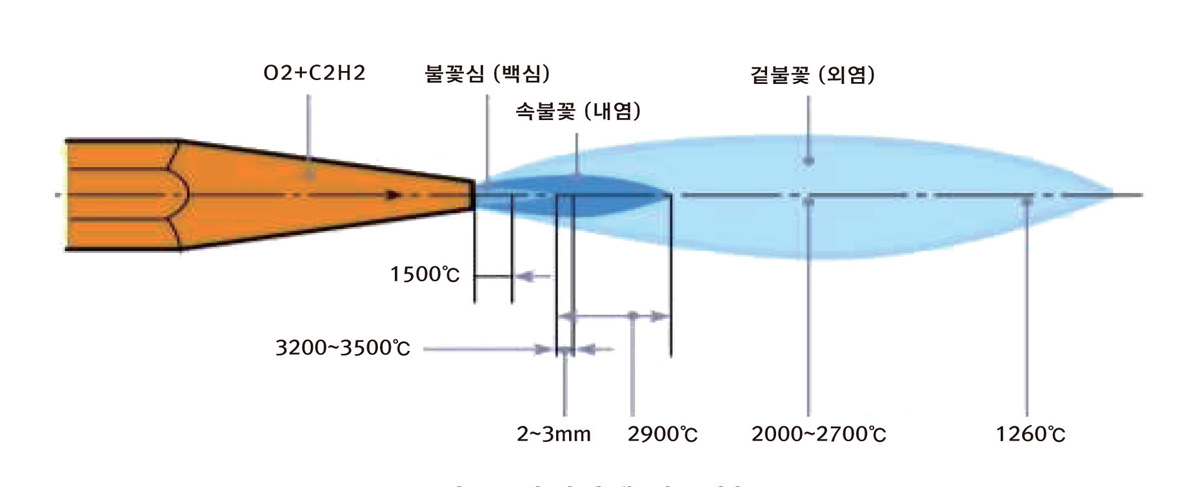

| Process condition |

Types of heat sources: oxygen + fuel Temperature of heat source: high temperature (3200 ~ 3500℃) Injection speed: low speed Base material temperature: over 500℃ |

| Process characteristics |

Provides excellent wear resistance and extended life in cutting and abrasion processes Formation of high coating thickness compared to other thermal spray processes Coating thickness is easily adjusted, so it is easy to repair products with severe wear |