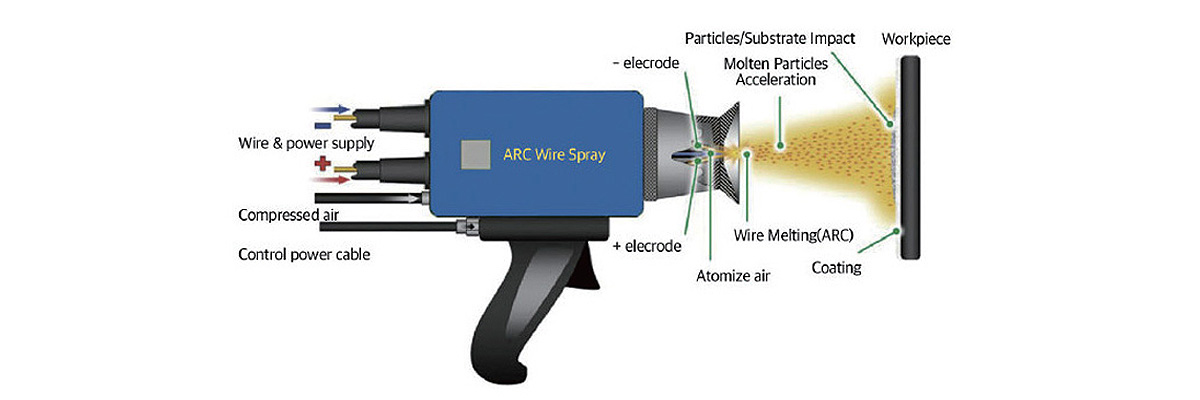

Arc Spray

Arc spray system

| Application field |

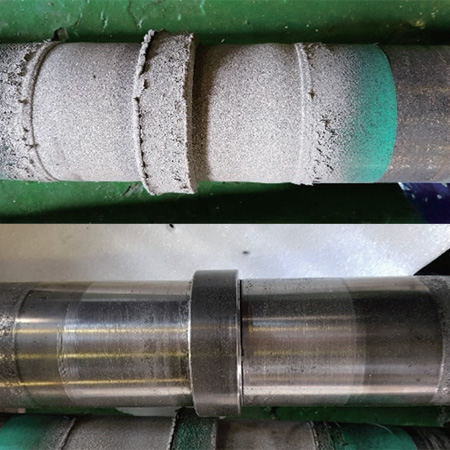

Restoration of worn shafts, bearings and sleeves and securing original dimensions Apply coating to anti-skid and friction parts Applicable to various parts such as metal, ceramic and plastic parts |

|---|---|

| Coating materials |

Type of coating material: wire rod Zinc/aluminum alloy wire Nickel/crop alloy wire Various alloy wire rods such as stainless steel, copper, zinc, aluminum, and Inconel |

| Process condition |

Types of heat sources: electric arc type using current voltage Temperature of heat source: 4,100 ~ 6,000℃ Molten particle scattering speed: 150 (m/sec) Adhesion (psi) : 7,000 |

| Process characteristics |

Method with the least thermal deformation of the base material Protective layer formation and economical coating method of a wide range of base materials Simple coating equipment and easy process management Coating material is limited to wire, and coating layer density is low Applies wear resistance, corrosion resistance, heat shielding, electrical, insulation, and conduction properties depending on the coating material |