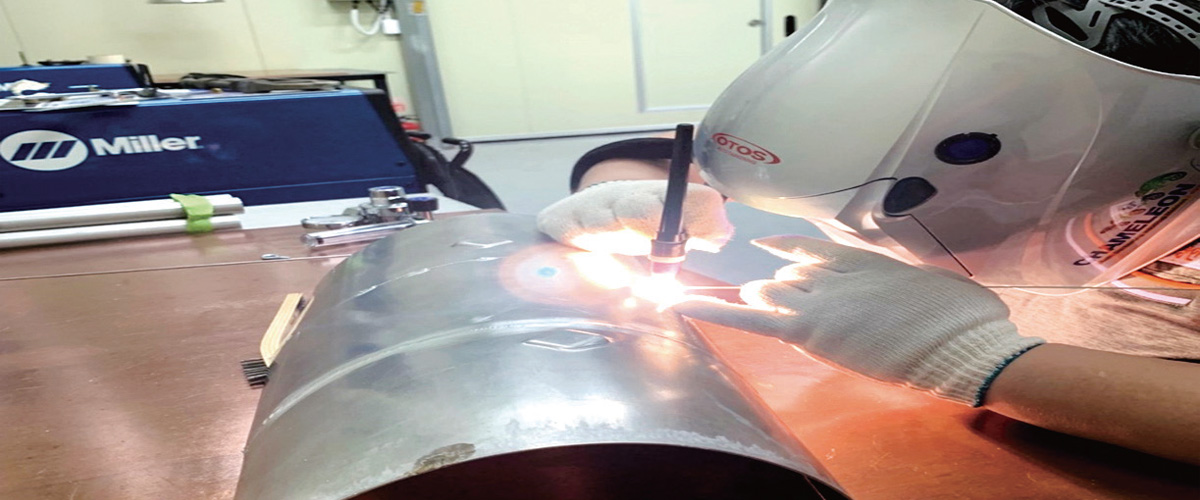

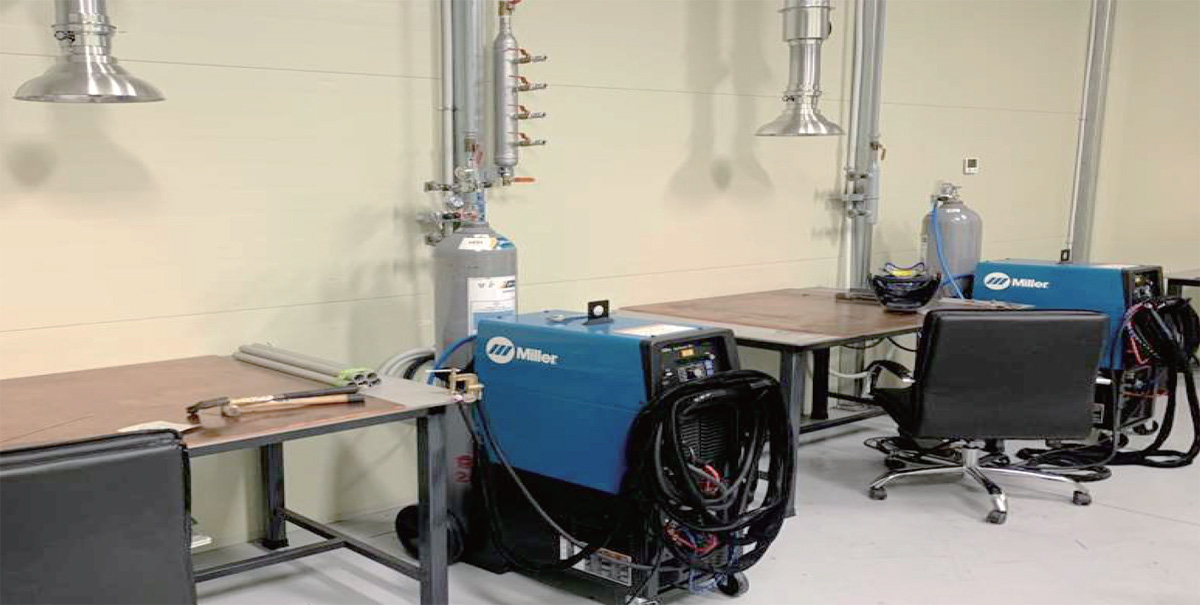

Tig Welding

| Application field |

welding of nonferrous metals such as aluminum, magnesium, and stainless steel Production of Aerospace Parts All industries requiring high-quality welding |

|---|---|

| Coating materials |

Use welding rods suitable for base material (AWS D17.1)

Aluminum welding rod: ER4043, 5356, etc Steel welding rod: ER347 etc |

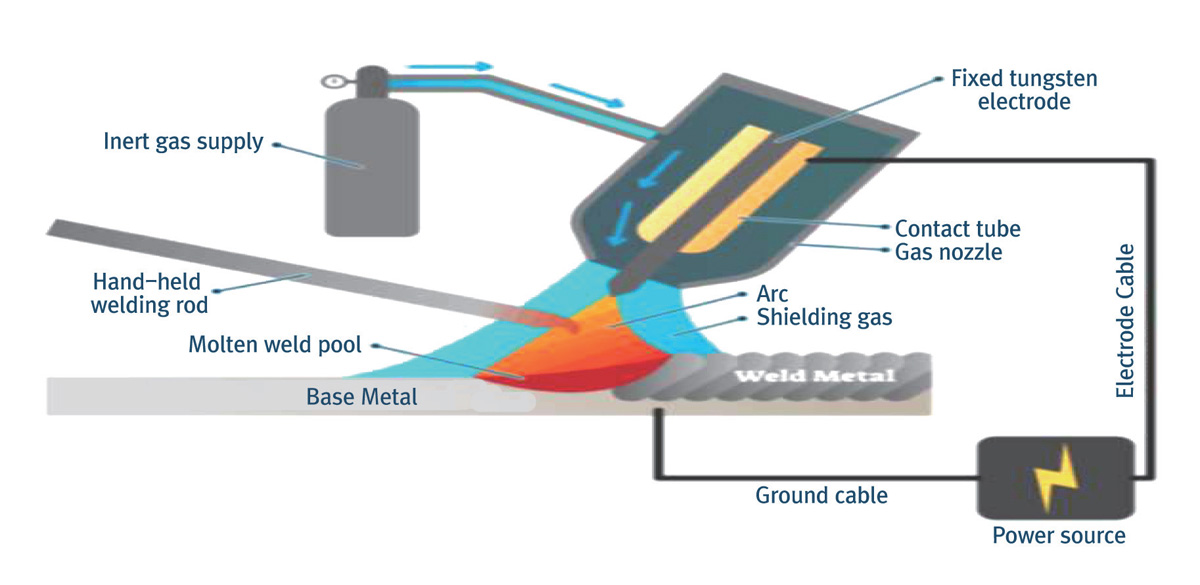

| Process condition |

Electrode: Non-consumable tungsten electrode (melting point 3,400°C) Shielding gases: inert gases such as argon, helium, etc Welding method: Current supply using foot pedal |

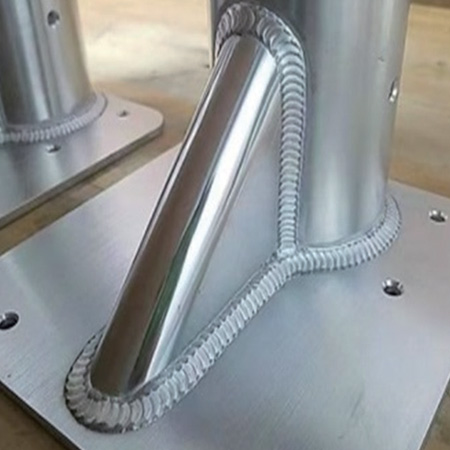

| Process characteristics |

Heat input adjustment is possible during welding, making it easy to weld thin sheets Less impurities mixed and better arc stability Welds are less deformed and no slag is generated High-quality and high-purity welds compared to other bonding processes |