Laser Cladding

Laser construction methodis classified into direct heat treatment method for molds and products and overlay for products.

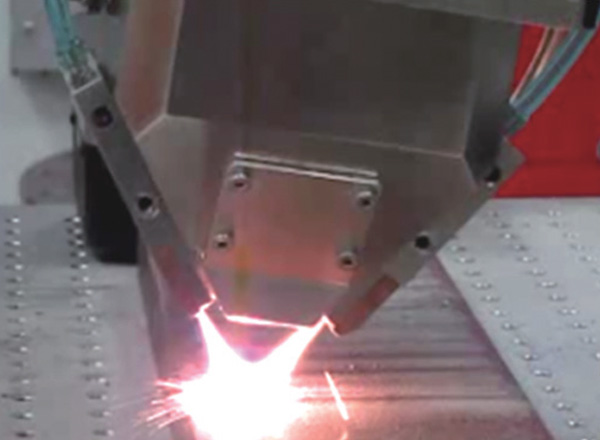

Heat treatment - Surface hardness can be improved using a laser alloying beam.

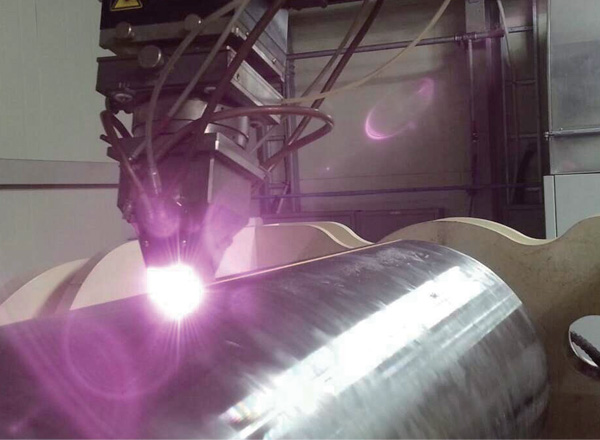

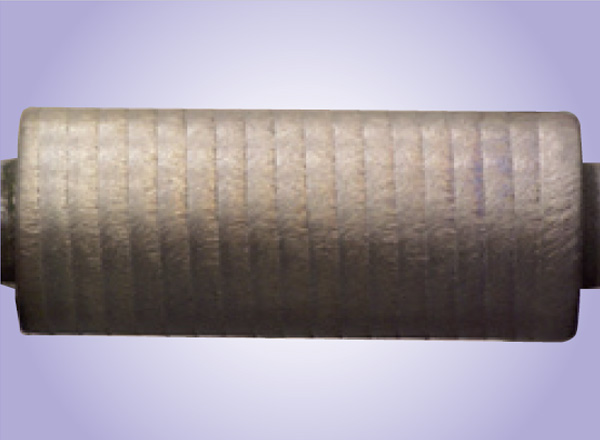

Overlay - Durability (hardness) can be improved by forming a metallurgical bond coating using metal powder or wire to form a surface layer of the product.

1. Minimized thermal deformation compared to conventional heat treatment due to the characteristics of the laser

2. Possible to repair existing wear parts (Overlay)

3. Applicable to various products and materials by using multiple metals and wires

4. Dramatic reduction in mass production and maintenance costs

Application fields : Wear-resistant, corrosion-resistant, heat-resistant metal parts and parts requiring high hardness

Ironmaking : Guide rollers, shafts, various rolls

Power plant : Gas turbines, blades, various shafts

Other industries : Ball valves, pump rotors, impellers, ship engine parts, etc.